Material Testing

Corrosion tests are performed on finished or semi-finished products to detect potential manufacturing defects or assess a product's resistance to corrosion. Mechanical tests, on the other hand, are used to characterize the physical properties of materials, such as hardness or elastic stress.

Material Analysis

Material analysis mainly involves determining their chemical composition and structure. Techniques used include metallography, EDX analysis with SEM, as well as spectrometric analyses such as ICP-OES, infrared, and ICP-MS.

Study, expertise, research, and development

The different sectors in which we operate provide us with a comprehensive view of the industries. This diversified expertise is a key asset for our clients, who benefit from solutions tailored to their specific needs.

At Métalab, we conduct various environmental tests to assess the durability of materials. We perform salt spray corrosion tests, sulfur agent tests such as thioacetamide, synthetic sweat tests, climatic tests, and UV aging analyses. These methods allow us to simulate different usage conditions and identify the performance of materials in diverse environments.

We combine Vickers microhardness (HV) tests with Shore A or D hardness tests to precisely assess the mechanical properties of various materials. These thorough analyses enable us to deliver solutions tailored to our clients' specific requirements, ensuring the quality and reliability of the materials tested.

Vickers microhardness (HV) gfs fg

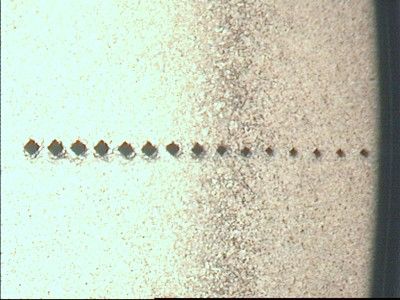

Microhardness measurements help control the homogeneity of a material between its core and surface. They are also used to verify the effectiveness of heat treatments, such as quenching, tempering, structural hardening, or annealing. Additionally, these measurements allow for the analysis of hardness gradients and the control of hardness values obtained after processes like carburizing, nitriding, or cementing.

Shore A or Shore D hardness

The Shore hardness scale is used to measure the hardness of elastomers, certain plastics, leathers, and woods. It is divided into two main scales: Shore A, used for soft materials, and Shore D, for harder materials. For example, this method can be used to evaluate the aging of watch seals.

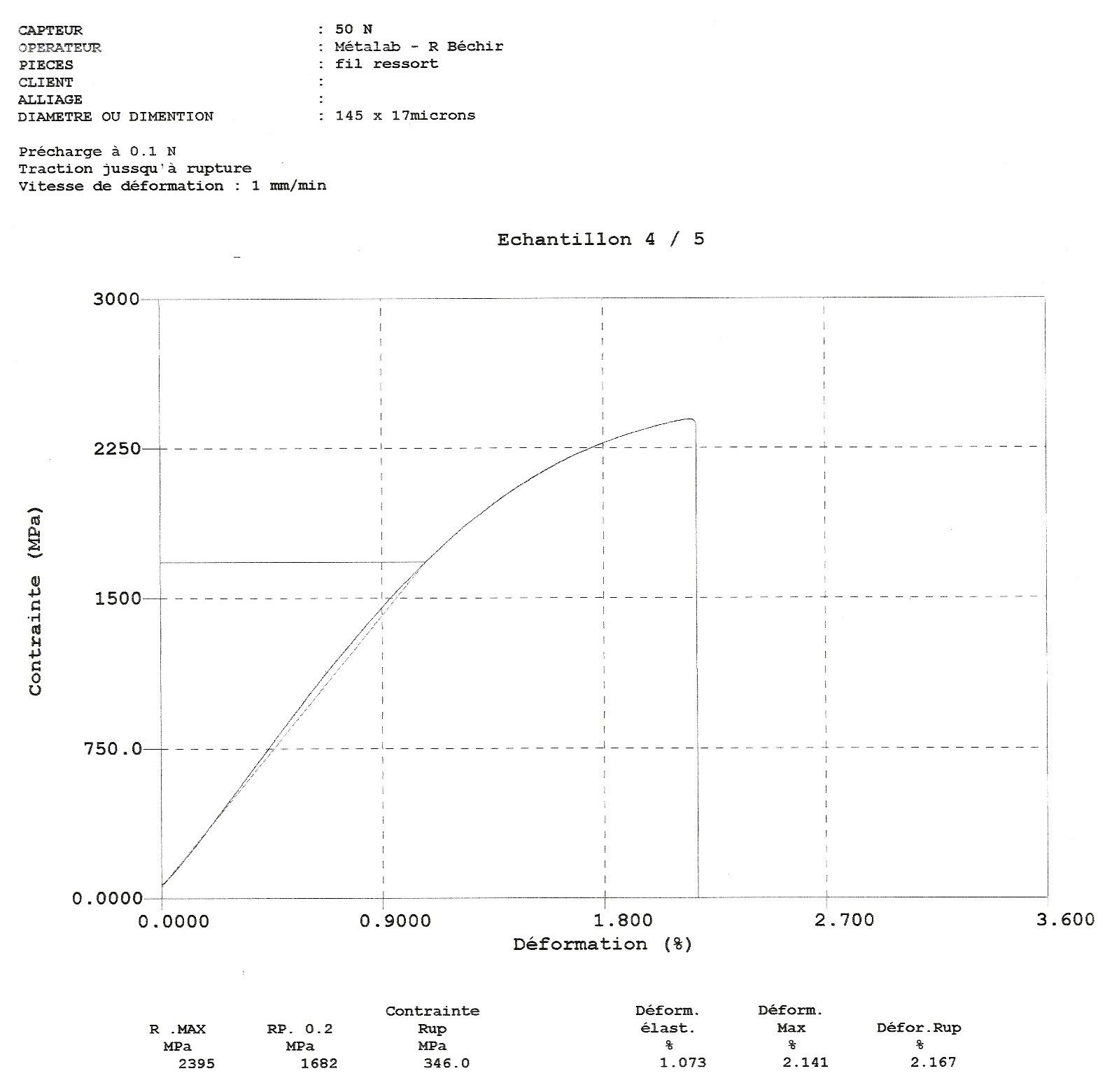

Mechanical tests

Mechanical tests can be classified into two categories: dynamic or static. Among the tests performed are tensile testing, compression testing, fatigue testing, and creep testing. These tests can be conducted on wires, rods, or strips cut into specimen shapes.

Below are some examples of tests conducted in our laboratory.

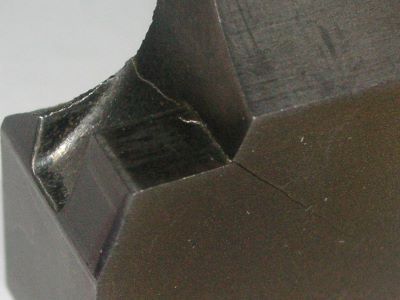

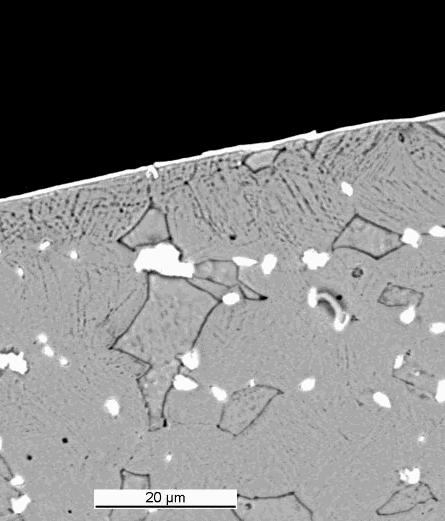

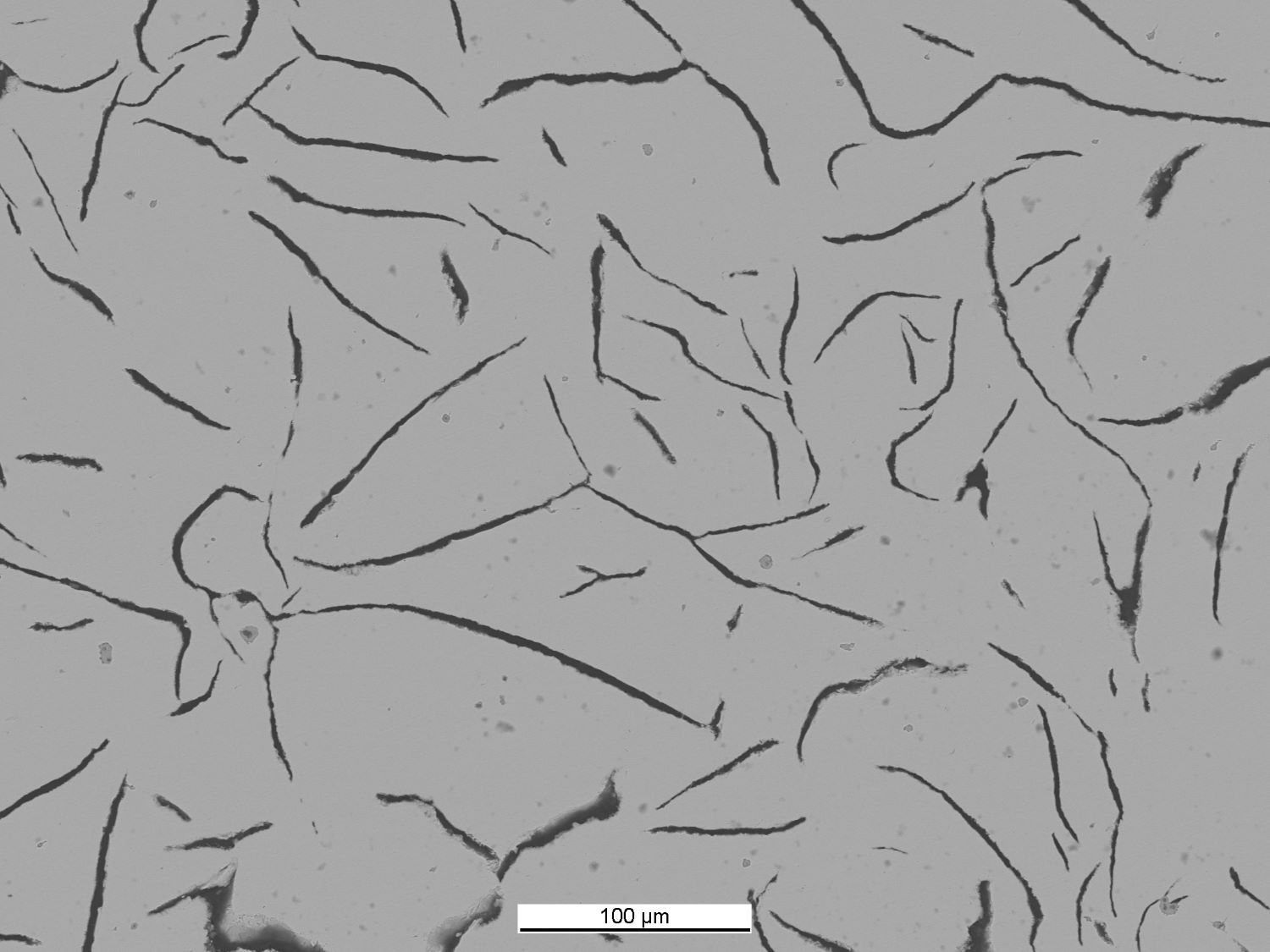

Hardness profile of a carburized part Cracked steel part

Below are some examples of tests conducted in our laboratory:

ON-SITE ANALYSIS: PORTABLE XRF ANALYZER

We offer a wide range of material analyses to ensure their quality and compliance. With our expertise, we perform precise analyses, ranging from chemical composition determination to microstructural examination. Our services include macrographic examination to observe visible characteristics, fluid analysis to control oils and galvanic baths, and microstructure study to identify phases and detect potential impurities. These analyses allow us to guarantee optimal performance and perfect control of the materials used.

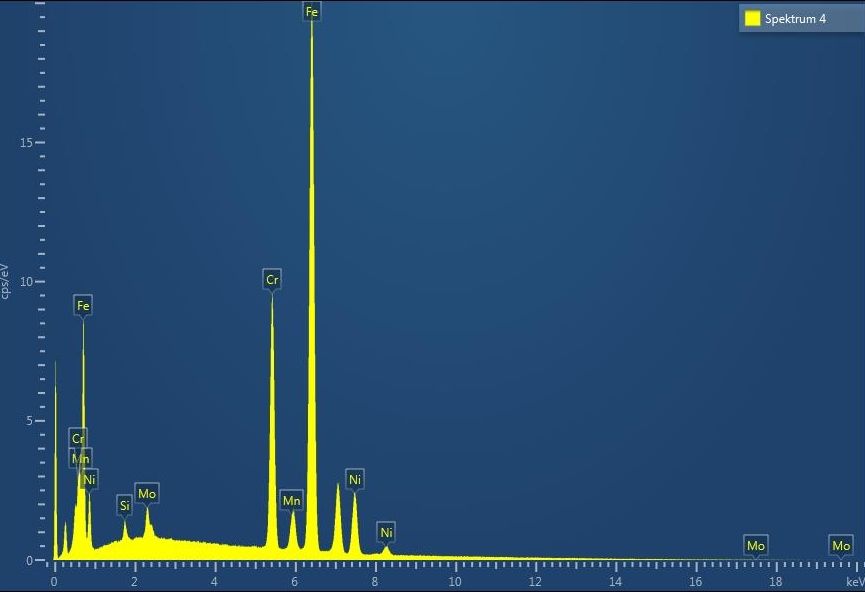

DETERMINATION OF CHEMICAL COMPOSITION

The chemical composition of materials can be determined using EDX microprobe analysis with SEM or spectrometric techniques (spark, ICP, IR). These methods allow for the identification of elements present in brass, steels, stainless steels, and special alloys, as well as measuring the levels of carbon and sulfur.

MACROGRAPHIC EXAMINATION

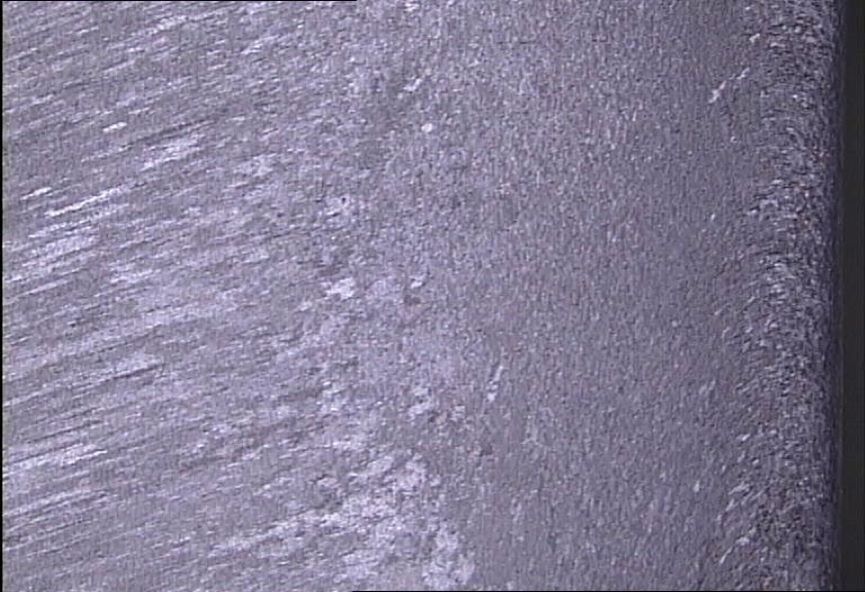

Micrographic examinations allow for the analysis of the internal structure of materials, including the fiber orientation of cast parts, revealing their texture and homogeneity.

FLUID ANALYSIS

Fluid analysis allows for the control of the quality of oils, galvanic baths, and wastewater to ensure their proper functioning and compliance with standards.

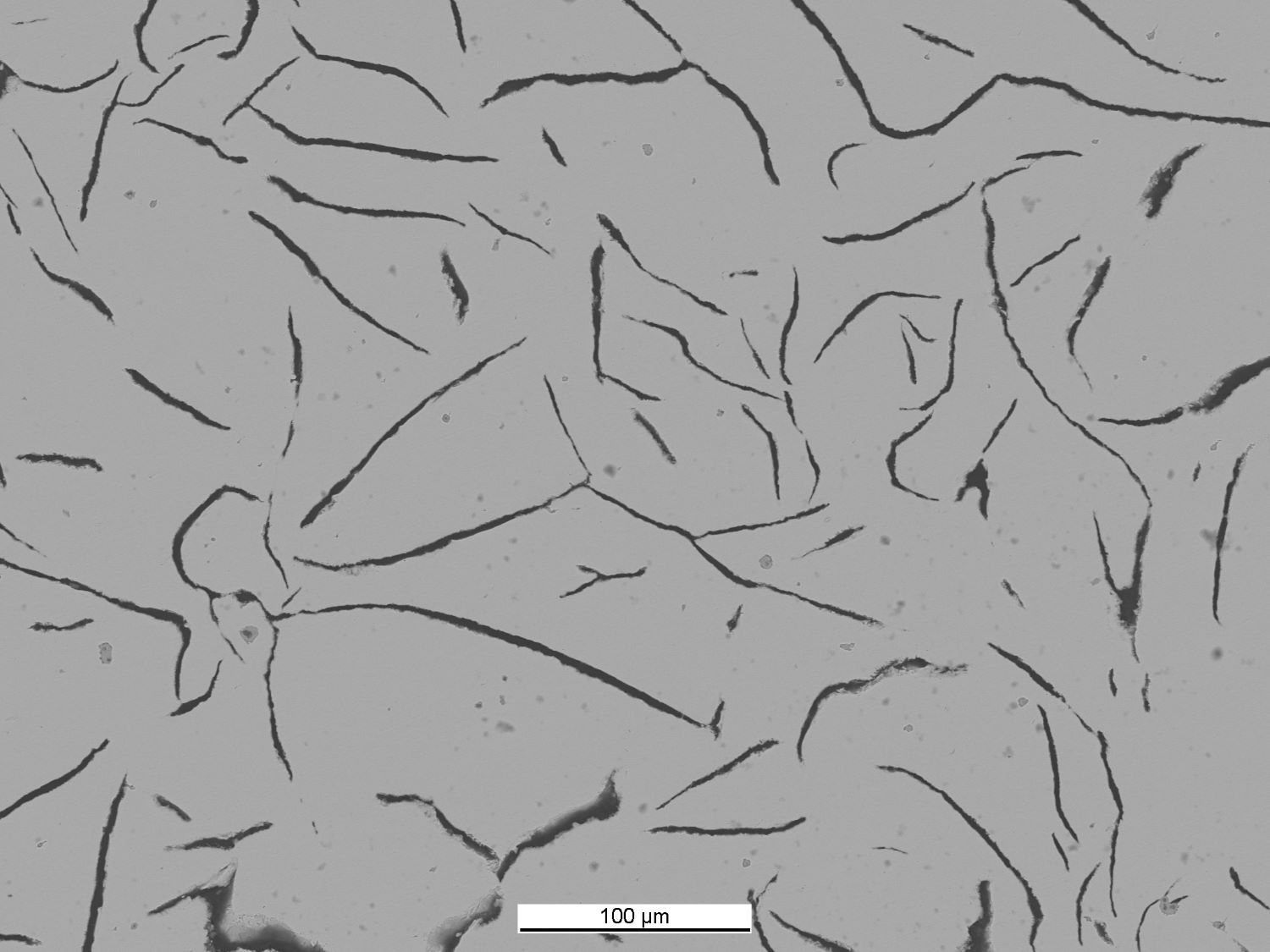

EXAMEN MICROSTRUCTURAL

Microstructural examinations allow for the identification and characterization of a material's microstructure, highlighting its phases, as well as any potential impurities or porosities.

CHARACTERISTIC MICROSTRUCTURE OF A GREY CAST IRON

We offer a wide range of material analyses to ensure their quality and compliance. With our expertise, we perform precise analyses, ranging from chemical composition determination to microstructural examination. Our services include macrographic examination to observe visible characteristics, fluid analysis to control oils and galvanic baths, as well as microstructure study to identify phases and detect potential impurities. These analyses allow us to ensure optimal performance and complete control over the materials used.

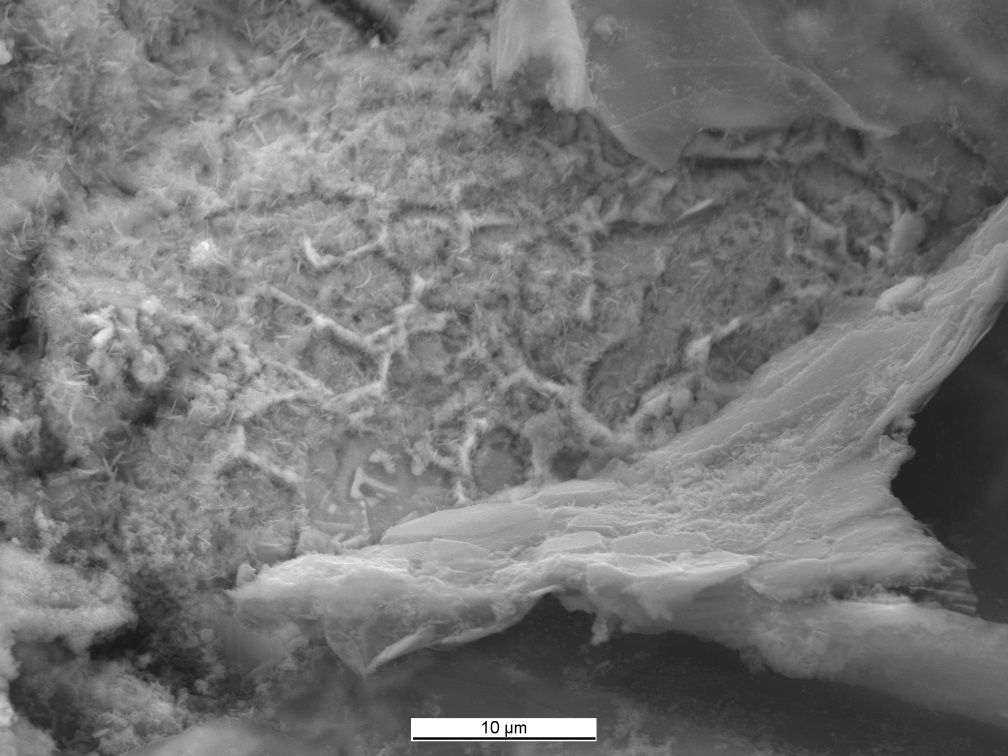

Expertise

The analysis of fracture faces in cast iron helps identify the underlying issue and determine whether the fracture is ductile, with plastic deformation, or brittle, occurring without prior deformation.

...

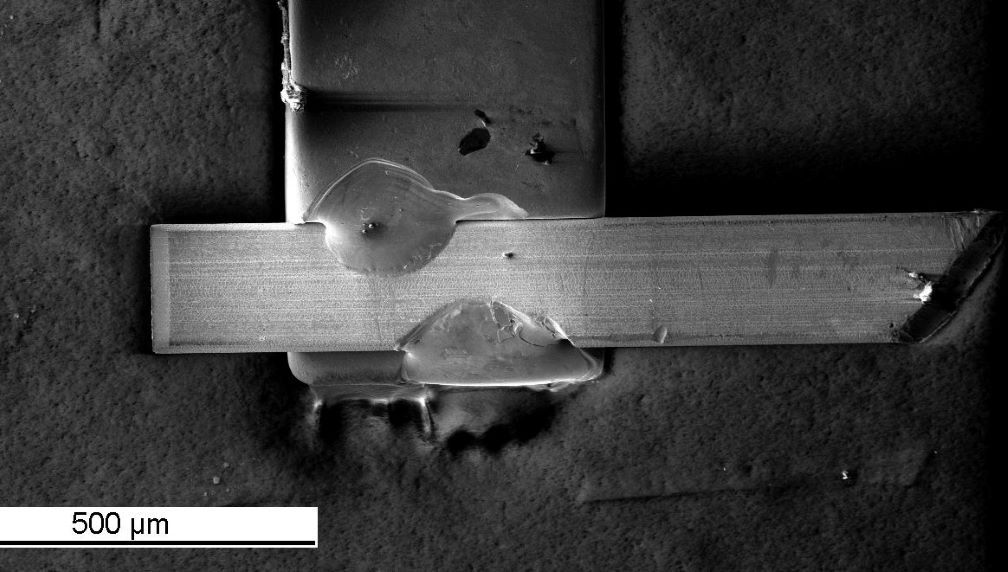

Process Optimization

We help you choose the materials best suited to your welding needs. Among our services, we optimize welding parameters such as temperature and time, and we ensure material compatibility to prevent corrosion issues.

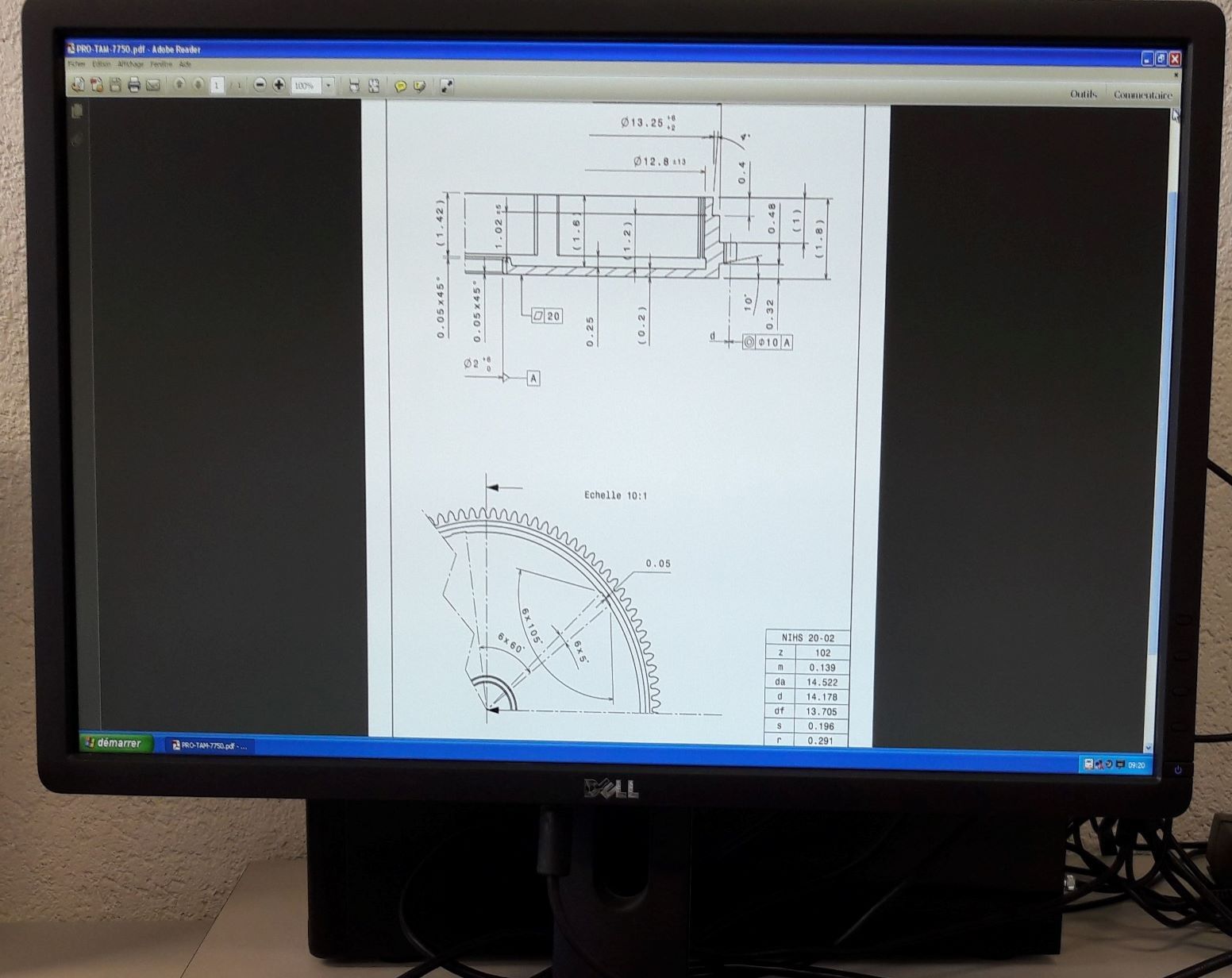

Development of New Materials

We specialize in composite materials, particularly carbon fibers. Our projects include spiral springs, barrel springs, lightweight aluminum alloys, synthetic diamond pallets, and tribological coatings with low friction coefficients.